Lincoln Electric System

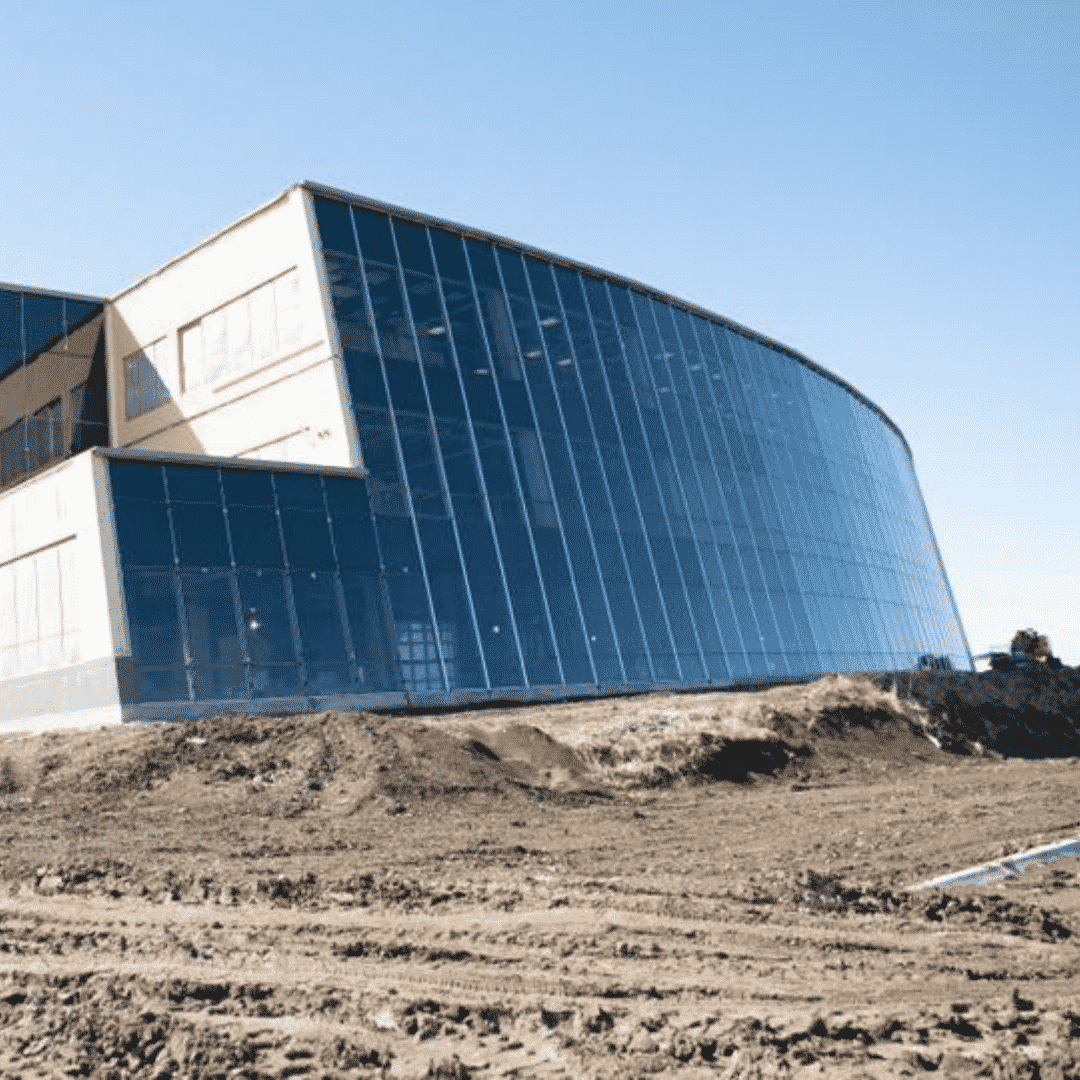

Capitol City Electric partnered with Hausmann Construction to complete this $100,000,000 facility.

LES PHASE 001

LES PHASE 002

Summary

Words from Our Project Manager

According to Project Manager Kyle Holman, all exterior walls for the facility are either precast panels or glass curtain walls. Precast panels are concrete walls that are poured and made in an offsite location and then shipped to the job site. Due to conduits needing to be recessed in each wall panel, the conduit routes are coordinated through BIM prior to being put into production. Since the walls are poured and made in a controlled environment, precast walls offer better quality and more affordable solutions than their counterparts, despite weighting up to 20,000 lbs.

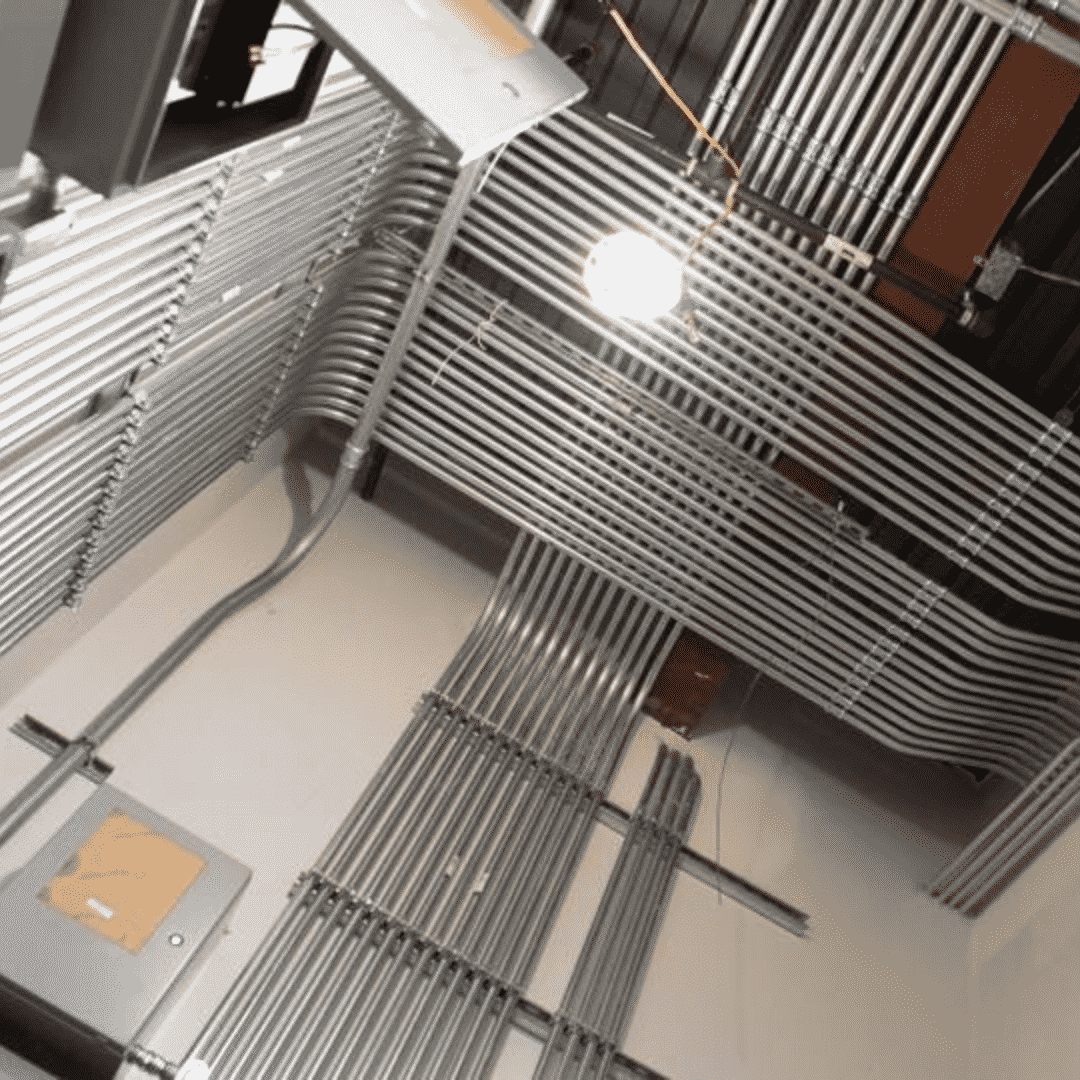

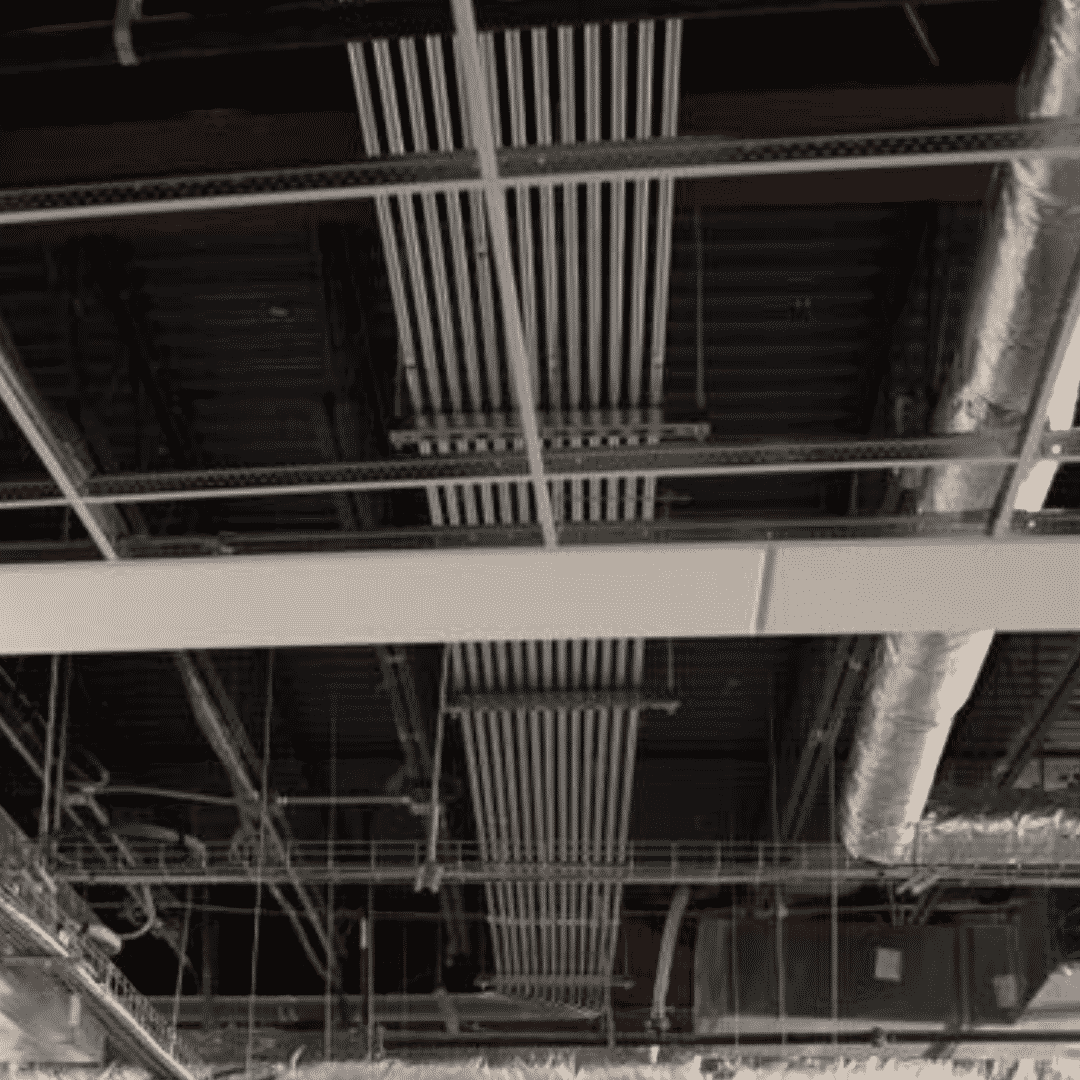

What fascinates Kyle the most is the amount of forethought and organization the project requires. Kyle explains, “each trade is required to coordinate their work with BIM and get approval prior to installing anything. This requires a lot of coordination by every trade but in return, helps eliminate potential disputes in the field.” Throughout the BIM process, CCE is able to capitalize on many pre-construction and pre-fabrication opportunities.

Efficiencies

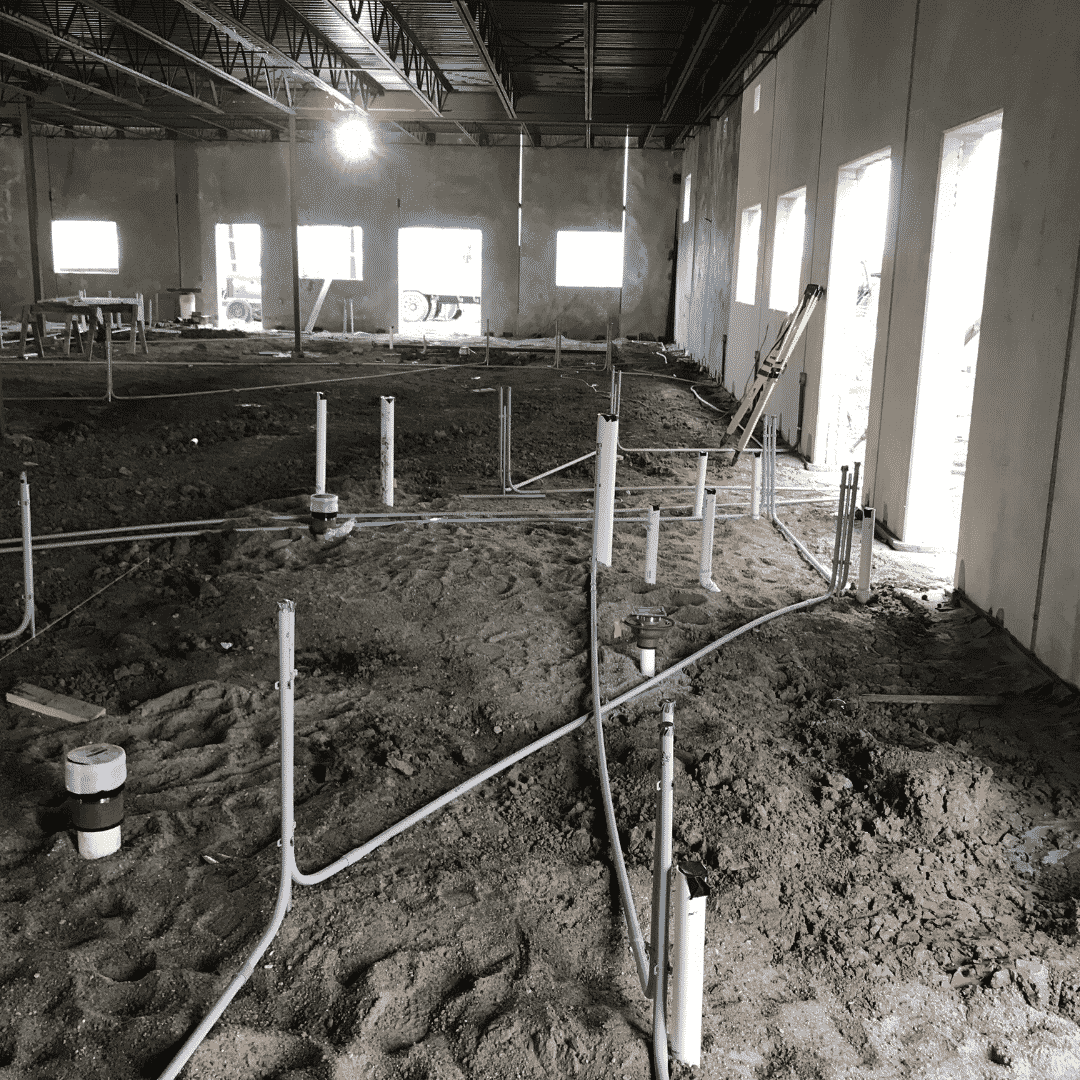

These opportunities include branch conduit racks, lighting j-box layouts, wall elevations for electrical device layouts, and major conduit routes. The Trimble RTS is another important robotic tool that goes hand in hand with the BIM process. The Trimble tool is being used on LES Phase II to locate electrical equipment rooms, conduit stub-up locations, cable tray hangers, and more. The time savings of the Trimble has been extremely beneficial and is used on most CCE commercial projects.